Why Do Combustible Dust Standards Exist?

The National Fire Protection Agency (NFPA) is the organization that sets combustible dust regulations and standards. The new standard which will go into effect in Fall of 2024, is NFPA 660 Standard for Combustible Dusts. This new standard will combine the existing standards NFPA 61, NFPA 484, NFPA 652, NFPA 654, NFPA 655, and NFPA 664.

Each of the NFPA regulations apply to certain types of facilities, protecting workers from combustible dust hazards, including spontaneous fires and explosions. Some of the types of workplaces that have combustible dust standards include:

- Agricultural & Grain Storage

- Food Processing

- Combustible Metals

- Sulfur Processing

- Woodworking and Wood Processing

There is a serious risk of dust explosions with industrial processes that handle combustible dusts. For safe operation, NFPA standards permit the use of enclosureless dust collectors, based upon specific criteria differing upon the application type.

The streamlined standard will simplify the process of determining which regulations apply to a particular facility, enhancing protection against combustible dust hazards. Moreover, the unified code negates the need to buy several documents to adhere to different combustible dust standards. It offers all necessary guidelines and information under one roof, providing a more straightforward approach to maintaining safety and compliance.

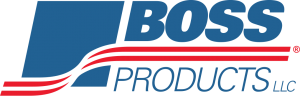

Basic Diagram of Spark Detection and Fire Suppression System

Current Combustible Dust Standards

These are the current NFPA Standards in 2023:

- NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Feed Processing Facilities

- NFPA 484: Standard for Combustible Metals

- NFPA 652: Standard Fundamental of Combustible Dust

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions from Manufacturing, Processing and Handling of Combustible Particulate Solids

- NFPA 655: Standard for Prevention of Sulfur Fires and Explosions

- NFPA 664: Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

These will be combined into NFPA 660 Standard for Combustible Dusts.

In addition to these, the following NFPA standards also exist to help make workplaces safer.

- NFPA 68: Standard on Explosion Protection by Deflagration Venting

- NFPA 69: Standard on Explosion Prevention Systems

- NFPA70: National Electrical Code (NEC)

NFPA® 484: Standards for Combustible Metals

According to recent OSHA reports, 30% of dust explosions are started by mechanical sparks. The most recent version of NFPA 484: Standard for Combustible Metals was released in 2015 to help mitigate potential explosions in the metalworking industry. The cost of preventing industrial dust explosions is necessary, but could be expensive. Wet dust collectors can reduce this cost significantly in comparison with dry dust collectors.

NFPA 484 applies to all who are involved in any way in the “production, processing, finishing, handling, recycling,

storage, and use of all metals and alloys that are in a form that are capable of combustion or explosion” (NFPA 484-15, paragraph 1.1). All who are involved should be fully conversant with the provisions of NFPA 484 and shall comply in full with all of its various requirements. Specifically detailed in this standard are the “light metals” that are aluminum, magnesium, niobium, tantalum, titanium, zirconium, and hafnium.

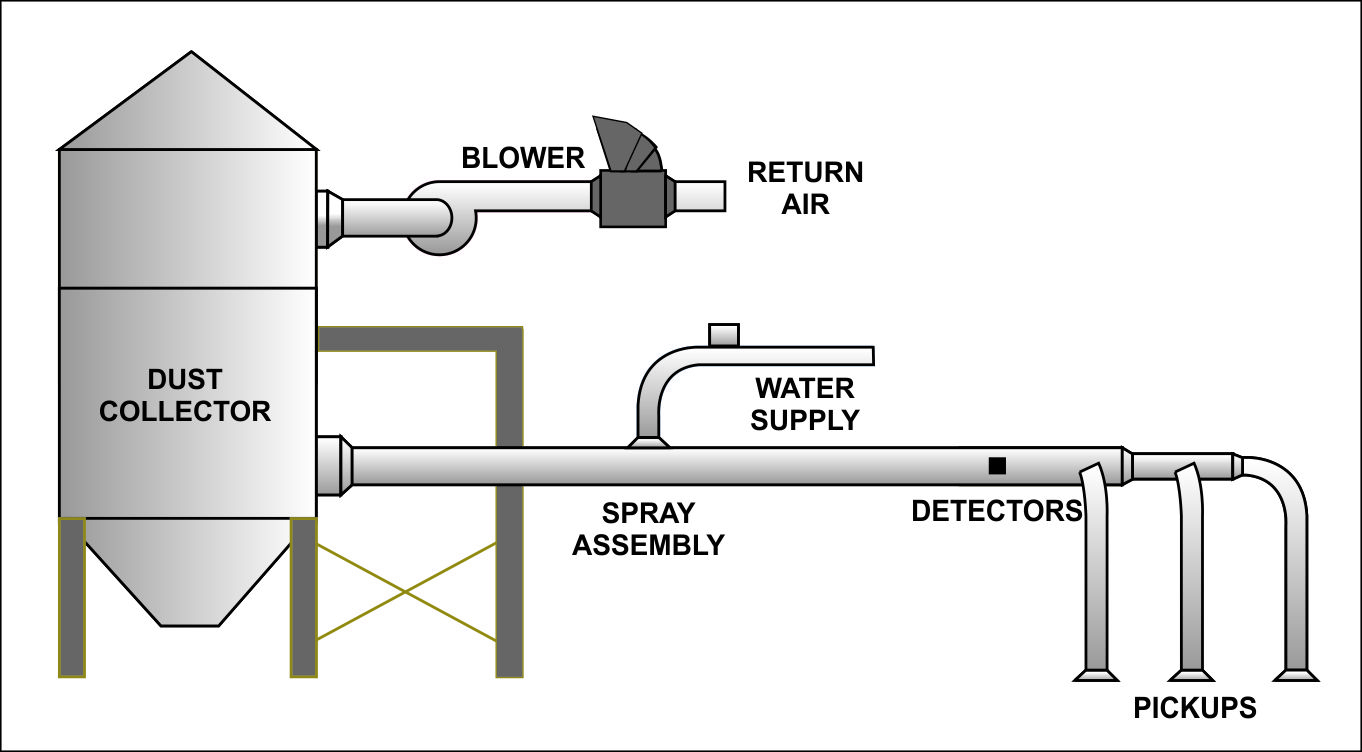

Conditions for a Dust Explosion

A dust explosion can only occur when the following five factors are present.

- Fuel in the form of dust particles.

- Dispersion of the fuel in the form of a dust cloud.

- Oyxgen in the form of air.

- Confinement of the dust cloud in an enclosed space.

- An ignition source.

These five factors form the explosion pentagon (as adapted from OSHA SHIB 07-31-2005; updated 11-12-2014). By controlling or eliminating just one of these key factors, the risk of a dust explosion decreases dramatically.

Wet dust collection eliminates some of the factors that contribute to dust explosions. Dust than has been made wet has a drastically less chance of exploding. The transfer of the dust from the air removes it from an oxygen rich environment. Without oxygen combustion cannot occur. The use of water eliminates any potential source of combustion. This also eliminates the need for spark detection and extinguishing systems. Since the dust has been eliminated from the air and is now in a “wet” state there is no mechanism by which a dispersed dust cloud can form.

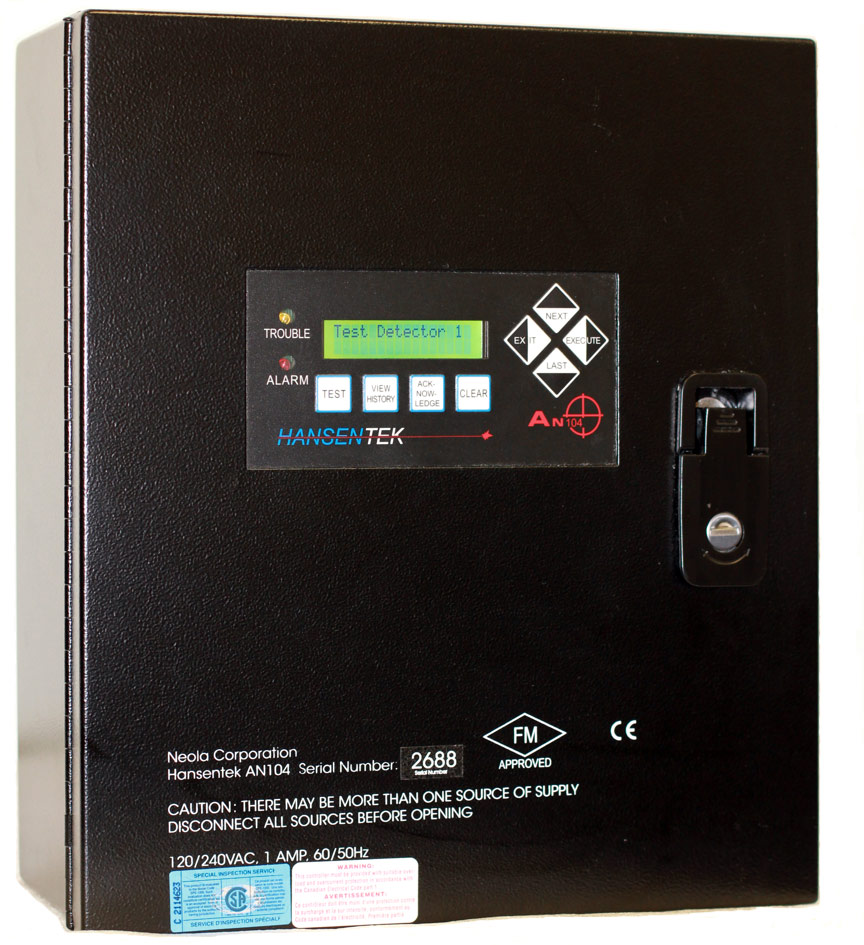

NFPA Standards, Combustible Dust, Spark Detection Systems

Hansentek AN104 Spark Detection and Extinguishment control panel.

Facilities that process materials with combustible particulate in the air, such as wood dust, combustible metallic dust, oil or lubricant mist, or grain dust, must have spark detection and fire suppression systems to prevent workplace accidents.

Many production facilities produce combustible dust and under the right circumstances, this dust particulate can ignite or even explode. Special spark detection, explosion suppression, and fire suppression equipment can help eliminate potential hazards caused by dust.

Abort gates used in spark detection systems

Wood dust or fabric particles in wood processing, furniture factories, textile mills and other factories can produce flammable dust that must be properly collected to prevent fires. Chemical processing, pharmaceutical production, recycling facilities and other similar processing plants also have combinations of gases and particles that require specialized dust collection and fume extraction equipment to meet NFPA standards.

Grain storage, and food processing, like for sugar, starch, and flour, all require stringent dust collection and spark detection, and these particles can be extremely flammable, even when suspended in the air of the processing plant. Metallic dust, fertilizer factories, and metalworking foundries are also potentially hazardous due to combustible particulate and gases in the air. Metallic shavings from zinc, aluminum, or titanium—once airborne and combined with other gasses within a facility, can easily deflagrate, catch fire, and explode. Our team is very experienced with dust collection, fume extraction, and spark detection systems for industrial workplaces. Contact us if you need a consultation.

Combustible Dust and NFPA Specialists

Combustible dust is a mjor concern in many workplaces, we can help you set up explosion prevention and combustible dust suppression systems designed to prevent workplace accidents. Contact us for more details.