The AirCoast Advantage – Baghouse Dust Collectors

Advantages of Baghouse Dust Collectors

Can be Used in High Temperatures. One big advantage is baghouse dust collectors can withstand higher temperatures than cartridge dust collectors. For industrial settings where the air being filtered is above 250° F, baghouse dust collectors are the best filtration solution.

Versatility. Baghouse dust collector systems can be used in wide variety of applications. When particulate comes in a range of sizes, baghouses are a good choice. Particularly where dust particulate is more than 50 microns, baghouses are a reliable solution.

Sticky Materials Can Be Filtered. Sticky or adhesive particulates are more efficiently collected in a baghouse dust collector. Bag filters are able to release sticky materials easier than cartridges, so cleaning cycles are easier.

Can Handle a Heavy Dust Load. For workplaces where a high amount of dust is being filtered, baghouse dust collectors are usually the best art filtration solution. Baghouse dust collection systems are great for dust particulate 1 micron and above.

Heavy Durability. Baghouses are known for being particularly durable under heavy loads. Fabric bag filters are durable, flexible, and typically have a longer life span than cartridge filters, meaning filter replacements are less frequent.

Scientific Dust Collectors® Supersonic Pulse Jet Top Removal (SPJ-T) Collector

Scientific Dust Collectors® Supersonic Pulse Jet Top Removal (SPJ-T) Collector is designed with a full walk-in plenum for easy bag access from the clean side. It utilizes the Patented UniFlow Supersonic Nozzle™ cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life.

The SPJ Series is a heavy-duty reverse pulse jet dust collector that operates continuously without requiring the process to be shut down for cleaning. The walk-in feature on the SPJ-T Series allows bag change out from the clean side while not being exposed to the elements. Our high side baffled inlet with dropout section slows to less than 3000 FPM, which allows the large particles to simply fall out of the airstream into the hopper. Our bag spacing of three (3) inches between bags is the widest spacing in the industry. This reduces re-entrainment of the dust.

Scientific Dust Collectors makes use of their nozzle based cleaning system that eliminates the venturi at the top of the bag/cage. This allows for over 300% more cleaning air into the bag than other baghouses. We guarantee a stabilized pressure drop in our baghouse to be lower than 3.5″WC at full rated airflow. Optional built-in Hepa final filter housing makes this a great solution for a variety of applications.

Scientific Dust Collectors Supersonic Pulse Jet Top Removal (SPJ-RT) Dust Collector

Scientific Dust Collectors® Supersonic Pulse Jet Railing Top (SPJ-RT) Collector is designed for easy top bag removal from the clean side while maintaining low headroom. It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life.

This design has all the same benefits and features as their walk-in plenum design. The only difference is that the bags are accessed through “lift-off” doors on the roof of the baghouse. The Railing Top design allows bag access from the top of the collector without the added expense of a walk-in plenum.

Scientific Dust Collectors® Supersonic Pulse Jet Bottom Load Dust Collector

Scientific Dust Collectors® Supersonic Pulse Jet Bottom Removal (SPJ-B) Collector is designed for low-profile applications where headroom is a factor. It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life. This design also has all the same benefits and features as our top bag access designs. The only difference is that the bags are accessed from the dirty air side of the baghouse.

ATEX version available. Certified for potentially explosive atmospheres. Several configurations available. Choose among different arrangements, heights, or discharge systems.

Customizable final layout. Optional hopper, motorfan, and acoustic enclosure. Used for bulk material handling, silo venting, material packing, and more.

PulsePak® Prime

The PulsePak® Prime is a compact dry dust collector that can be used where dry dust load is high and water is not available. It can be used in applications where the air temperatures are higher, up to 270º F, making it ideal for furnace ventilation and other hot work applications. Using a true DOWNFLOW design where dislodged dust free-falls straight to the hopper, it has a lower differential pressure than competitive designs.

Though the PulsePak® Prime is a pleated cartridge dust collector for a large capacity in a small footprint, it is a unique dust collector that essentially operates as a baghouse collector.

The PulsePak® Prime dry dust cartridge collector provides a high filtration efficiency at a wide range of air flows, from 3,000CFM up to 90,000CFM. Its small footprint is due to the unique filter vertical arrangement of AAF’s proprietary pleated cartridges.

The PulsePak® Prime operates with less internal turbulence than conventional models. The PulsePak® Prime’s unique filter cartridge arrangement provides a more compact design, which allows for maximum flexibility when meeting space requirements. Large hinged access doors allow for minimized inspection and cartridge change-out time since multiple filter cartridges can be externally accessed through one door.

By using a venturi design, the PulsePak® Prime cleans more efficiently. The PulsePak® Prime is equipped with REDClean® Media, allowing it to offer best-in-class filtration. Many different media options are also available.

This is the only DOWNFLOW cartridge collector on the market that uses 100% of the media, 100% of the time.

Donaldson Torit® RF Baghouse Series

The small footprint of the RF combines a cyclone precleaner and a baghouse into one unit. It features a powerful yet energy-efficient cleaning system, eliminating the need for compressed air to clean the bags. Combined with the revolutionary Dura-Life™ “Twice the Life” bag filters, or our new Ultra-Web® SB pleated bag offering, the award-winning RF gets the job done while using much less energy than competitor collectors.

Dura-Life bag filters are engineered with a unique hydroentanglement process that uses water to blend the fibers. This process provides a more uniform material with smaller pores, better surface loading, and better cleaning. These advantages provide twice the operating life before bags need to be replaced due to high pressure drop. Longer life from Dura-Life bag filters lowers maintenance and operating costs and raises baghouse dust collection to a whole new level.

The Ultra-Web SB Pleated Bags option provides spunbond pleated filters with our Ultra-Web fine fiber web-like net to capture dust on the surface of the filter. These filters reduce emissions and provide longer filter life which reduces maintenance and downtime costs.

LP Baghouse Series by Donaldson Torit

The LP series by Donaldson Torit is a continuous reverse air cleaning baghouse designed for for large airflow applications. The Donaldson Torit® LP Baghouse dust collector provides superior bag filter cleaning performance in a reverse air design. This unique system design reduces your maintenance cost and downtime.

The LP advantage has a cleaning arm with a flow-stop plate that keeps air from flowing through the bag filters before and after cleaning. Dust from cleaned bag filters cannot be re-entrained onto adjacent bags, resulting in lower pressure drop and reduced energy costs. Combine this with Dura-Life™ “Twice the Life” bag filters as standard and this LP Baghouse is better than any other reverse air collector on the market today.

Dura-Life bags are made from polyester material that is created through a hydro-entanglement process instead of a needle punch process. The hydro-entanglement process creates a more consistent and uniform filter material. The material is comparable in thickness to standard polyester, but weighs about 1/3 less. The fibers are smaller and the hydro-entanglement process creates a loftier and lighter weight fabric that filters more effectively.

Rugged Pleat Baghouse Dust Collectors

The Donaldson Rugged Pleat (RP) Baghouse sets a new standard for baghouse dust collector performance, combining advanced collector design with superior filtration technology in our most maintenance-friendly design ever.

The award-winning Rugged Pleat Baghouse is ideal for the heavy and/or abrasive dust applications typically found in woodworking, mining, grain processing, and other industries. Combining a cyclone pre-cleaner and baghouse into a single unit, the Rugged Pleat handles heavy dust loads and large air volumes and uses a PD pump cleaning system to provide energy-efficient filter cleaning. But, the Rugged Pleat goes even further, incorporating advanced Donaldson filtration technology that leaves the competition behind.

The Rugged Pleat baghouse also offers a new, easy-to-use control panel. It provides at-a-glance monitoring of the complete system, so you know that your Rugged Pleat collector is running at optimal performance.

Cyclone Dust Collectors

Cyclone dust collectors are often used as prefilters in conjunction with baghouse and cartridge dust collectors. Cyclone dust collectors remove large dust particles to ease the dust loading on baghouses and cartridge collectors.

Using mechanical design, the largest particles are removed from the air flow before going to the baghouse for final filtering.

The Donaldson Torit® Cyclone dust collector is designed specifically for high dust load, high temperature, and product recovery applications. It has a mechanical separator that uses centrifugal force to remove dust particulates from the air in industrial applications.

Dusty air enters the cyclone and the dust particles travel around the inner wall of the cyclone. As the particles lose their velocity, they drop lower in the cyclone until they drop into the receptacle below.

ArrestAll®

The ArrestAll® is a shaker style baghouse dust collector, a compact and efficient solution to small and medium volume dry dust problems. Designed to control dust from a single source or system, the ArrestAll® saves energy by recirculating clean air. AAF dust control experts designed the ArrestAll® for many years of trouble-free, efficient service. Its design allows maximized airflow and efficiency.

Here are some of the benefits.

- Excellent filtration

- Self-contained operation to plug and play

- No compressed air required

- Compact design

- Mitigates combustible dust risk in ST1 dust applications

- Tool-less filter change

- Long filter life

What is a Baghouse Dust Collector?

Baghouse dust collectors use fabric or non-woven air filters to remove particulates, contaminants, and dust form the air in industrial workplaces. Dirty air enters the enclosure where the filters remove particles from the air, and the clean air is recirculated to the work environment. Dust particles collect on the filters, which is periodically removed using different methods, where it is collected in a waste hopper. Many industries use baghouse collectors to clean the air in their facilities, including in manufacturing, chemical processing, food production, woodworking, and aggregates.

How Does a Baghouse Work?

Baghouse dust collectors clear the air in an industrial workspace, removing particulate by filtering dirty air through bag-like filters supported by cylindrical cages. The filters may be fabric or non-woven material. Typically, baghouse air filtration units can handle air of high temperatures, making it versatile for heavy industry. Pleated bags may be used where the dirty air coming into the enclosure is less than 250° F.

Dirty air enters the baghouse unit, sometimes with a baffle knocking the largest particulate into the collection hopper. The dirty air passes through the baghouse filters, trapping the dust particles. Depending on the design of the baghouse, and the application, the dust may collection on either the outside or the inside of the filters. Every so often, the baghouse goes through a cleaning cycle, the dusts is knocked off of the filters, falling into the hopper.

Intermittent cleaning means the cleaning cycles take the unit or sections of the unit offline for a few minutes. Continuous cleaning, as in jet pulse baghouses, means the cleaning cycles happen continually throughout the day without going offline. The cleaned air exits the baghouse unit through a clean air outlet.

Types of Baghouses

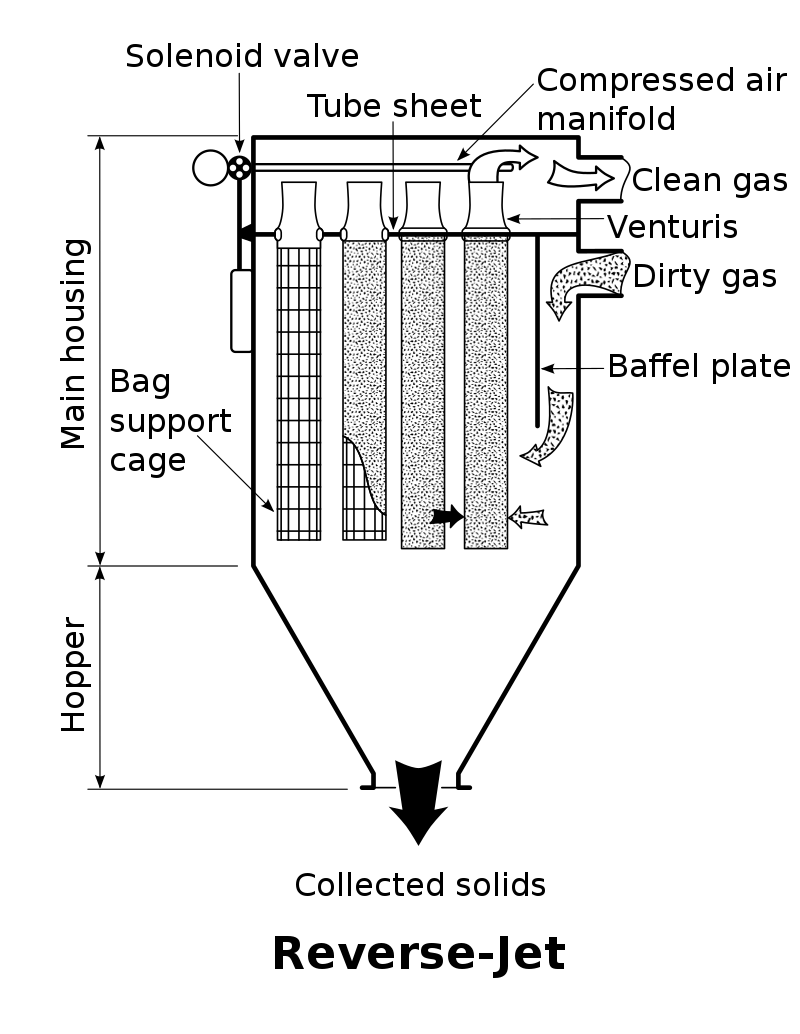

Pulse Jet

The most common baghouse is the pulse-jet or reverse-pulse baghouse dust collector. Pulse-jet dust collectors are highly efficient, with collection efficiencies of up to 99.99%. In this system, dirty air is moved through fabric filters supported by filter cages, usually moving the air upwards from the bottom of the unit. Dust collects on the outside of the filters. Even so often, a “pulse” of compressed air blows rapidly from the opposite direction of the airflow, causing a ripple effect which dislodges the caked dust from the filter. This dust then falls into a collection hopper at the bottom of the unit.

Pulse-jet baghouses are continuous cleaning, meaning the filtration unit does not need to interrupt the air flow to go through a cleaning cycle. This creates a cleaner work environment because the air filtration does not go offline for cleaning. Operating costs are low, outside of costs associated with compressed air.

The pulse-jet baghouse dust collection systems are well-suited for applications with air volumes of 1,000 CFM or more. Like other baghouses, pulse-jet systems work well in high temperatures, supporting airflow temperatures up to 500° F.

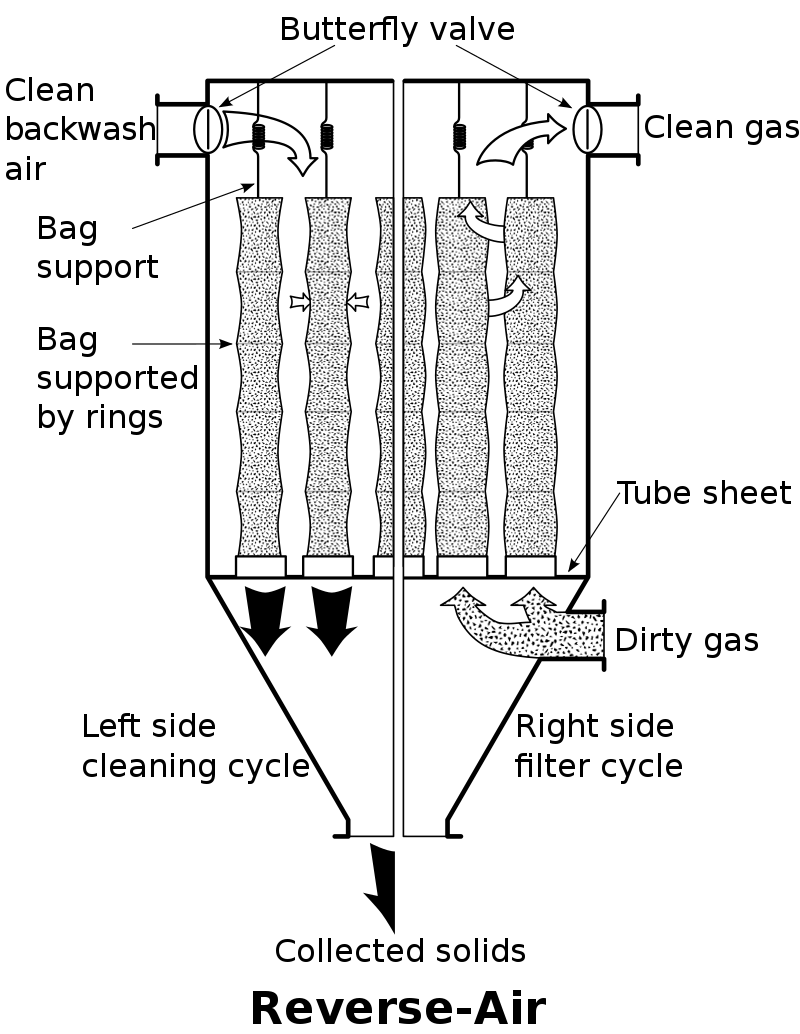

Reverse Air

Reverse air baghouses are used primarily in applications with combustible dust, such as steel mill electric arc furnaces, lime kilns, foundries and steel mills. The main differences between pulse-jet and reverse air baghouses, are with reverse air, the unit in compartmentalized, and the blown air is low pressure. A reverse air baghouse can handle high temperatures and supports certain types of filter media, like glass cloth, where low-pressure deflation is used to remove dust without damaging the filters.

Reverse air baghouses are continuous cycle cleaning, leveraging compartmentalization of the filter media. Clean compressed air is not necessary in reverse air dust collectors. Processed air is blown in the reverse direction of the dirty airflow to dislodge caked dust and particulate from the filters.

Reverse air baghouses are compartmentalized for automated, continuous cleaning without taking the baghouse offline.

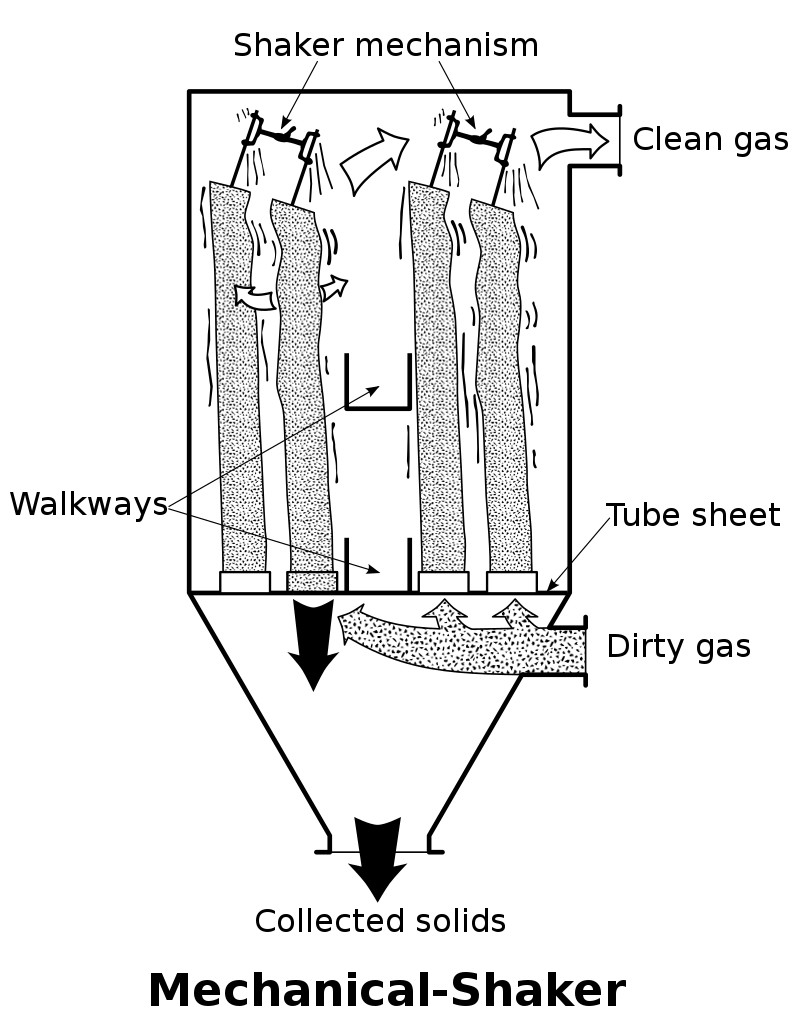

Mechanical Shaker

Shaker style baghouses use a motor driven mechanical system to clean the bags by shaking the collected dust off the filter while the airflow is paused to an offline baghouse. Larger shaker units compartmentalize areas, so the entire unit does not offline all at once. Specific compartments go through a cleaning cycle while others stay online.

Mechanical shakers have a low air-to-cloth ratio, so they require a larger amount of space to operate.

In a shaker baghouse, bag cages are attached to a floor plate, while dirty air passes through the insides of the filters. The tops of the bag cages are connected to beams at the top of the unit. During the cleaning cycle, the beams at the top of the unit shake the filter cages, dislodging the dust which falls into a collection hopper.

Need Help with Baghouse Dust Collectors?

The team of dust collection specialists at Aircoast Industrial Solutions are here to help you find the ideal system for keeping your workplace air filtered and contaminant-free. Contact us to discuss your workplace needs and we will help you find the perfect solution.